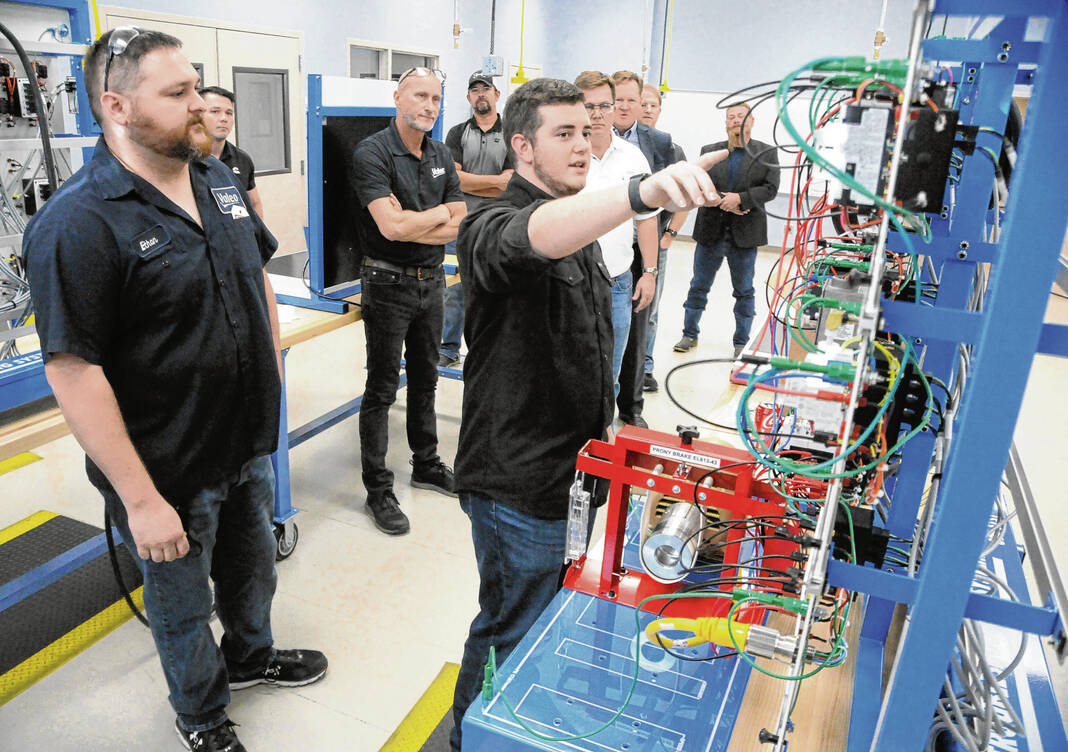

Cummins Inc. employee Drake Spencer talks about the circuit he built during the inaugural industrial maintenance — basic electrical course at the Jackson County Learning Center in Seymour. Valeo employee Ethan Heitz, far left, also was in the class.

Zach Spicer | The Tribune

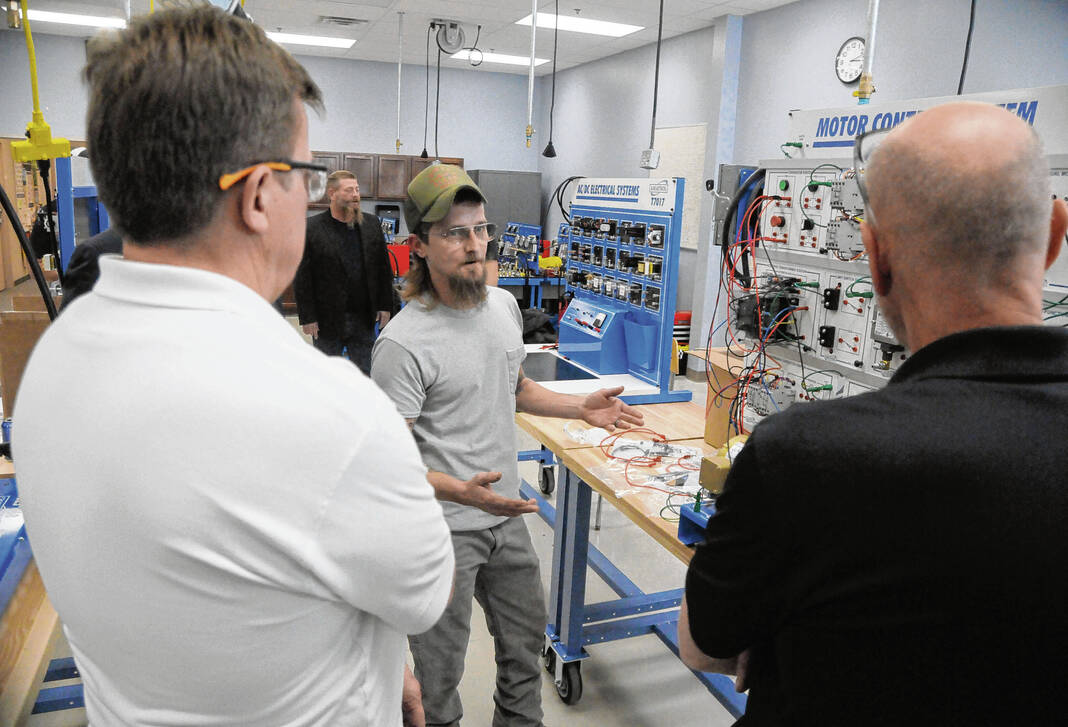

Valeo employee Shane Morris talks about the circuit he built during the inaugural industrial maintenance — basic electrical course at the Jackson County Learning Center in Seymour. Listening are Eddie Parr, left, and Wayne Brookes with Valeo.

Zach Spicer | The Tribune

The inaugural industrial maintenance — basic electrical course offered by Vincennes University at the Jackson County Learning Center in Seymour recently wrapped up. From left are site director and instructor Brian Sawyers, students Dylan Cowles, Shane Morris, Ethan Heitz and Drake Spencer, John Stein with Cummins Inc., student Adam Shuler, David Tucker with Vincennes and student Trapper Dean.

Zach Spicer | The Tribune

The inaugural industrial maintenance — basic mechanical course offered by Vincennes University at the Jackson County Learning Center in Seymour recently wrapped up. Kneeling from left are students Patches Coffman and Darrell McIntosh. Standing from left are site director and instructor Brian Sawyers, students Cristian Mendez, Junior Armstrong, Mario Ojeda, John Jones, James Collins, Trenton Owens and Sean Followell and VU Assistant Vice President Matt Schwartz.

Submitted photo

Cummins Inc. employee Adam Shuler was part of the inaugural industrial maintenance — basic electrical course at the Jackson County Learning Center in Seymour.

Zach Spicer | The Tribune

Valeo employee Dylan Cowles talks about the circuit he built during the inaugural industrial maintenance — basic electrical course at the Jackson County Learning Center in Seymour. Listening are Eddie Parr, far right, and Wayne Brookes with Valeo. Behind Cowles is Valeo employee and classmate Shane Morris.

Zach Spicer | The Tribune

On Nov. 9, a ribbon-cutting ceremony was conducted for the new industrial maintenance training lab at the Jackson County Learning Center in Seymour.

On Nov. 13, the inaugural courses — basic electrical and basic mechanical — started in the lab.

On Dec. 20 and 21, the students received their certificates of completion.

David Tucker, vice president for workforce development/community services for Vincennes University, encouraged a round of applause for site director and instructor Brian Sawyers for the work he put into getting the college’s lab up and going at the learning center, 323 Dupont Drive.

“A lot of schools will make a lot of big deal about the fact that they set up a lab and have it ready for training. There are lots of ribbon cuttings and groundbreakings and all that kind of stuff by schools touting what it is that they are going to do,” Tucker said. “What I’m particularly proud of in this instance is we opened this thing six weeks ago, and here we’ve got our first graduating class, so we didn’t mess around.”

Tucker said Sawyers did what he needed to do to finalize the lab so he was ready for the first day of class.

“A lot of that is attributable to the Jackson County Education Coalition and Jackson County Industrial Development Corp. and employers all saying, ‘Hey, look, we aren’t just building this thing for show. We’re building this thing for the future of our businesses here in town,’” Tucker said.

Not only were these the first two industrial maintenance classes at the learning center. They also were the first classes to be offered by Vincennes there.

They were free for the students thanks to their employers, Aisin USA Mfg. Inc., Valeo and Cummins Inc., making contributions toward the program.

“My philosophy in workforce training at VU is to provide you with skills that you can apply on the job your next shift that you go to work, and over time, we’ll get you in a few more classes and you’ll be able to build some skills that you can use over the long term,” Tucker said.

He thanked the students for taking advantage of the opportunity, having positive attitudes and working through hiccups along the way. He also encouraged them to go back to their workplaces and be cheerleaders for the program.

“I know your companies have invested a lot of time and energy into this program, and I think for you guys to be able to say, ‘Hey, look, here’s a way to hone your skills, here’s a way to build your skills right here in Seymour,’ with good trainers, good curriculum, hopefully, we can do that,” he said.

Finally, Tucker thanked company representatives for attending the graduation ceremonies and supporting the program.

“You guys have been here supporting this thing since we started talking about moving in here and building curriculum,” he said. “You guys have continued to support it with sending your employees here and supporting it in the plant. Our experience is that that mentorship that employees get back on the line is really key during the training and after the training.”

Sawyers said the classes went extremely well, and he had a good group of students.

“They have tangible skills that they will be able to take back to the workplace and be of value to the companies, so we appreciate that,” he said.

The 1,600-square-foot, state-of-the-art lab filled with high-quality equipment is a partnership between Vincennes, JCIDC, JCEC, the city of Seymour and Jackson County.

In July 2022, the Seymour Redevelopment Commission pledged its support to expand classes at the learning center. That allowed JCIDC Executive Director Jim Plump to continue to talk to local industries to get them on board since they mentioned a need for maintenance training.

If industries contributed and $240,000 was put in from the Regional Economic Acceleration and Development Initiative grant, the project could come to fruition. The total budget was $1.84 million, and the grant required a match of public and private dollars.

During meetings in May and June, Plump shared he had secured funding from local companies, and the redevelopment commission approved its contributions of $240,000 for 2022 and $240,000 for 2023. Part of the money was used to purchase equipment and hire an instructor.

The lab includes AC/DC electrical systems, electric motor control with troubleshooting, electronic sensors, mechanical drives, chains, belts and gears, pneumatics, hydraulics, motors with troubleshooting, bearings and lubricants, laser shaft alignment, vibration analysis and power and control electronics.

The intro courses consisted of time in the classroom next door for lectures and the rest of the time doing hands-on learning in the lab, Sawyers said.

Dylan Cowles was among the six students in the electrical course. He has worked at Valeo for five years and was a quality inspector but now is in the maintenance apprentice program due to knowledge and experience gained in the class.

“Just to move up in the company and get a skilled trade,” he said of why he took the class.

Having the opportunity to take the class for free was fantastic, he said.

“We’re getting paid to come here. We don’t have to work all day and then go to school in the evening on our own time,” Cowles said. “If it wasn’t for this program, I would still be in assembly as a quality inspector. I’m very thankful for it.”

Valeo employees Shane Morris and Ethan Heitz also completed the electrical course. Both are mold setters, Morris working there for a year and a half and Heitz working there for nearly 11 years.

“I just wanted to go up to the next level,” Morris said. “Now, I’m in the tool room. Because of this class, I’m able to do that.”

Heitz also wanted to advance at Valeo.

“I wasn’t able to advance higher in my position without having extra schooling and stuff like that,” he said. “I mainly took it not only to build my résumé but to work my way up the ladder at work.”

Neither of them knew about electrical maintenance before but now have new skills to apply at work.

“It seemed like a lot, and honestly, it was. In the beginning, it was just overwhelming, but there toward the end of the class, it all started to come together. Brian did a pretty good job with it,” Morris said.

“I really didn’t know anything other than the fact that electricity bites and hurts,” Heitz said, smiling. “When I first started, I didn’t really know anything. Now, I’m confident that I actually look at something and probably fix it. I’ve learned a lot in this class.”

Adam Shuler, Trapper Dean and Drake Spencer represented Cummins Seymour Engine Plant in the electrical course.

Shuler and Dean are production engineering specialists, while Spencer is a technical documentation associate. All have more than five years on the job at Cummins.

“I didn’t know anything, and then now, I know more electrical and electricity and how it works, not just flip the light switch and it comes on,” Shuler said.

He even was able to apply the skills he learned in the class at home. The pressure switch for his well pump went out and wouldn’t shut off, so he bought a voltage tester and a new switch and was able to change it and fix the problem.

“I would have never done that if I wouldn’t have taken this class,” Shuler said.

Dean said he also can now apply the skills he learned.

“The more knowledge we have, the more things we can do going forward with the company and home, as well,” he said. “I like doing home improvements and stuff, so it just gave me a little bit more incentive to do some wiring work.”

Spencer said he is trying to get into the mechanical engineering technician apprenticeship at work, so the industrial maintenance courses could help him accomplish that.

“Having this locally, especially being sponsored by Cummins, it’s great,” he said. “Instead of having to take an evening and having to go somewhere 30 minutes away, I’m grateful to be able to come here and do it during work hours, as well. That’s huge.”

In early 2024, there will be another round of intro classes. Then in mid- to late February, intermediate classes will start.

Learn more

For information about Vincennes University’s industrial maintenance courses at the Jackson County Learning Center in Seymour, contact instructor and site director Brian Sawyers at 812-525-9139 or [email protected].