In a year, Dr. Kristopher Williams said he performs around 300 knee and hip replacement surgeries.

He has done those by hand.

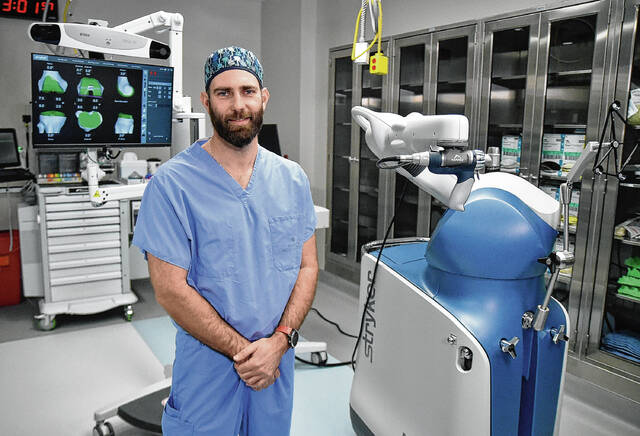

Now with new technology at his hands, he has a robot to help with the procedures.

In early January, Schneck Medical Center in Seymour became one of the few facilities in the region to receive Stryker’s Mako SmartRobotics. This advancement in joint replacement surgery transforms the way total knee, partial knee and total hip replacements are performed by helping surgeons know more and cut less, according to a news release from the hospital.

The innovative technology combines three key components — three-dimensional CT-based planning, AccuStop haptic technology and insightful data analytics — into one platform that has shown better outcomes for patients.

“With Mako SmartRobotics, I know more about my patients than ever before, and I’m able to cut less. For some patients, this can mean less soft tissue damage. For others, greater bone preservation,” said Williams, an orthopedic surgeon with Schneck Orthopedics and Sports Medicine. “Patients experience less pain, less blood loss, fewer days in the hospital and faster recovery in comparison to manual techniques.”

Williams recently said his first robotic-assisted joint replacement surgery is planned for Tuesday.

To be ready to use the technology, he spent two days in Las Vegas, Nevada, in December taking a certification course.

That taught him how to manipulate the software and help with the planning side of it.

“I’ve done thousands of joint replacements, so the surgery is basically the same, so it’s not like they were teaching me how to do joint replacement. That part I already know,” he said. “They were teaching me how to manipulate the new equipment. There’s a learning curve, but it’s pretty easy. It’s intuitive, and it just works how you want it to work. I was doing a version of this before, so I had the advantage of that. It’s just manipulating this machine.”

Williams said this type of technology for total hip and partial knee replacements has been around for nearly a dozen years, and he knew the plan was to release a platform for total knee replacements at some point.

“A total knee replacement, there’s a lot more that goes into it than a total hip as far as how much you can customize it to each individual patient,” he said. “That level of customization translates directly into patient satisfaction scores are higher, and in theory, the longer the implants are going to last.”

How accurately the implants are put in determines how long they are going to last, Williams said.

“With this robotic arm, it allows you to be extremely precise within a half-degree and half-millimeter, which that’s super precise, way more precise than a human hand can be,” he said. “I guide this arm, but it won’t allow me to go outside of my plan, which is in the computer.”

Before each surgery, Williams will take a CT scan of the patient’s anatomy. That is uploaded into the computer system, and then a Mako product specialist operates that as Williams performs the surgery.

On the CT scan, the white part is the bone, and green represents the implant.

“You can take the patient’s bone anatomy on the CT scan, which would be the white part,” Williams said. “You can basically mimic your surgical cuts on the bone and then put the green implants in there and get them dialed in exactly how you want them in there, so that’s how you plan it preoperatively. Then this robotic arm allows you to replicate that during surgery. This arm will not allow me to go outside of what my plan called for.”

Williams said the reason he asked Schneck administration to add the technology and allow him to earn the certification is because of the benefits for the patients.

“The patient is going to feel like the knee is more stable, they are going to be able to trust the knee, and that comes with just the precision of how we’re able to balance them,” he said. “Patient satisfaction scores go up because they think, ‘Oh, this is a knee that’s going to work for me, I can trust it when I’m going up and down stairs’ and that kind of thing, so that takes that up a notch.”

With a high number of factory workers in the area, Williams said working on concrete floors wears out the knees.

“I have 40-year-olds that are needing joint replacements, and so we do everything we can to treat them without that, but when it comes to it and you’ve tried everything else and they’ve failed all of the other conservative treatments, eventually, you have to do a joint replacement,” he said.

Rachel Stangland, the operating room manager at Schneck, said considering the benefits of the up-to-date technology, it was easy for administration to see the importance of having it at the hospital.

“We do have a lot of joint replacements from this area. Arthritis seems to be a common thing in Indiana,” she said. “What it’s going to do is allow us to just really take that already great level of care that they were getting and just take it up to the next notch, so they are going to have that world-class, big-city total joint replacement care right here in Seymour.”

She and Williams both said that might be available at large hospitals in Indianapolis or Louisville, but it’s not common to have it offered in a local setting like Schneck.

“People do their research when it comes to health care now, so to be able to go right next door to Schneck where your family and friends are taking care of you and be able to have that big-city, top-notch technology is really a great benefit to people,” Stangland said.

It also streamlines the hospital’s processes in surgery suites, she said.

“It helps us conserve resources and just do things more efficiently and effectively,” she said. “That’s why that technology is really going to be great to have here. It’s awesome. If I was going to have a total joint replacement, that’s what I would want.”

Williams said Schneck administration is always looking to the future and trying to keep up with the latest technology, and adding Mako SmartRobotics further demonstrates the hospital’s commitment to providing its communities with outstanding health care.

He said he’s excited to use the technology.

“The great part about being an orthopedic surgeon is you’re changing people’s lives. They go from not being able to walk, not being able to keep up with the grandkids and stuff like that, and you replace their knee and it’s like they have their life back,” Williams said. “I’m looking forward to seeing what the outcomes are, and I have no doubt they are going to be improved.”

At a glance

For information on joint replacement surgery and Stryker’s Mako SmartRobotics, call Schneck Orthopedics and Sports Medicine at 812-524-3311 or visit schneckortho.com.